RAW MATERIALS

We use the most suitable mixtures to minimise waste during casting.

Established in the late 1980s, our company caters for foundries offering automatic forming with the cold box process and manual forming with the furan process, coating with a drying oven, and storage.

We use carefully selected raw materials and guarantee the quality of all our finished products, from samples to large batches.

We use the most suitable mixtures to minimise waste during casting.

We offer advice during each stage of the process, starting with design of the patterns, as well as post-sales customer service.

Two production lines are used during two shifts to process orders ranging from samples to large batches.

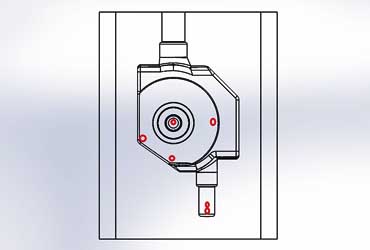

Our team of specialists use state-of-the-art machinery to produce cores of all sizes, including ones weighing as little as a few grams.

We offer a daily oven-drying service, to guarantee quality of the coating even in the coldest months.

We carry out packaging with care, using materials that can ensure safe transport of the cores.